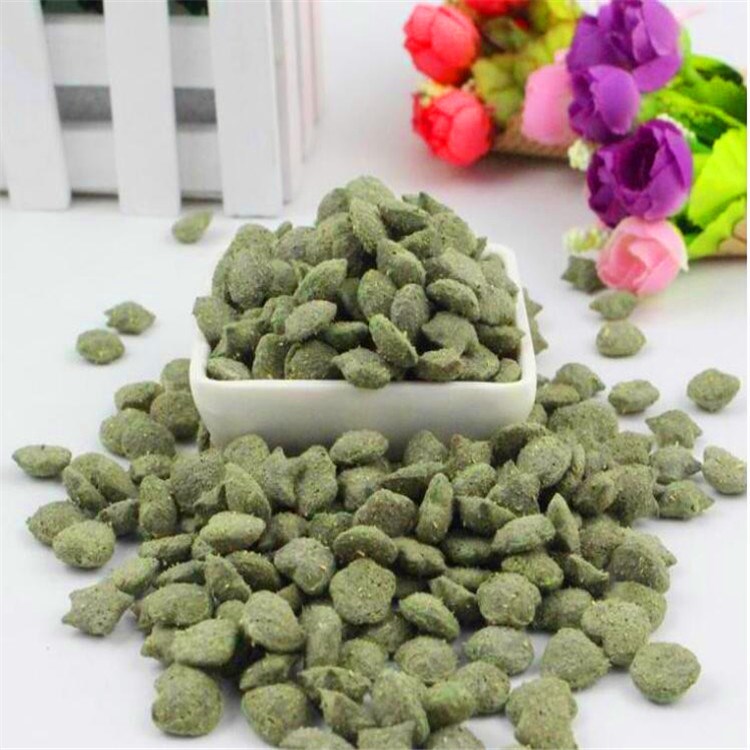

- 产品描述

的狗粮生产设备厂家,必须具有多年生产经验,销量多,经验丰富。

选择稳定的狗粮加工设备,需要对其机型有所全面的了解。

目前市场上有家用单螺杆狗粮生产设备,商用双螺杆狗粮设备两种。

家用型配置简单,价格便宜一般几千到一万左右,其加工狗粮技术简单,故障率高。容易堵 。

生产的狗粮品质也得不到保证。

一般买过的顾客都比较清楚,清理非常费时费力,膨化熟化度也不好。

中小型狗粮设备生产流程

一、狗粮机狗粮生产设备狗粮生产线工艺流程:

原料配制→拌料→输送→挤压膨化→输送→干燥→喷油→调味→冷却→筛选→包装

二、狗粮机宠物饲料生产线狗粮饲料膨化机生产线 配置:

拌粉机→上料机→膨化机→输送机→多层烤箱→调味线→冷却输送机→震动筛→包装机

大型狗粮设备生产流程

自动配料系统---粉碎混合系统---膨化烘干系统---喷油调味系统。

Production process of small and medium-sized dog food equipment

1、 Dog food machine dog food production equipment dog food production line process flow:

Raw material preparation → mixing → conveying → extrusion → conveying → drying → oil injection → seasoning → cooling → screening → packaging

2、 Dog food machine pet feed production line dog food feed extruder production line configuration:

Powder mixer → feeding machine → extruder → conveyor → multi-layer oven → seasoning line → cooling conveyor → vibrating screen → packaging machine

Production process of large dog food equipment

Automatic batching system - crushing and mixing system - expansion and drying system - oil injection and seasoning system.

中小型宠物生产线设备可以广泛适用于狗、猫、鱼虾、、鸟及各种宠物饲料的生产,是刚性需求生产厂家比较理想的选择。该生产投资小,产量高,占地面积小,自动化运行程度高等特点。整机使用不锈钢材料加工。保证卫生整洁。膨化制粒技术使用双螺杆挤压膨化技术。

中小型宠物食品食品生产线根据生产工艺分为两种生产方式:干法生产和湿法生产,干法生产就是原料混合后直接在双螺杆膨化机膨化制粒,这种干法生产一般以谷物粉为主,添加少量的熟化肉粉,产能在100-200kg/h之间;湿法生产工艺就是原料混合后在膨化之前添加一个调制过程,调制就是物料与热蒸汽在调制器内充分的混合,0.25MPA蒸汽压力下停留3分钟左右,将原材料的蛋白质熟化和淀粉糊化,湿法工艺生产蛋白质的添加量要**干法生产的蛋白含量,因为湿法的工艺淀粉调制过程中糊化较好,在膨化时具有较好的粘滞性和。在干法膨化机的加工基础上添加调制器以后,产能方面会有显著提高。同时也会降低电能消耗和机械磨损。

膨化后的狗粮含有大量水分,必须进行脱水干燥处理,选用不用型号的膨化机配套匹配产量的烘干设备,根据能源选用电热型、燃气燃油型、蒸汽加热型。根据烘干原理可以选用普通带式干燥和饲料带式干燥根据投资需求选用。饲料带式干燥机投资较高,产量大,能耗低。普通带式干燥机投资低,能耗**饲料干燥机

宠物市场的发展与壮大是必然之势,由此带来的宠物食品需求不需多说。但是,在宠物食品加工上,到底市场前景如何呢?

据统计,全年我国的宠物行业销售额已经突破了1800亿元币,照此趋势,今年的年销售额可达到2000亿元以上,成为国民经济发展的重要支柱产业之一。可以说,我国的宠物行业发展整体呈现上升利好状态,在此时借入做宠物食品加工,必将大有可为。

两种狗粮加工工艺:1、干法膨化在生产加工中需要在原料中添加水分原料在进入膨化仓之前不进行预调质处理,膨化过程中所产生的热量全部由原料在机械挤压的作用下通过螺杆、剪切板和膨化腔内产生。一般适用于中、小宠物食品加工厂家。

The development and expansion of the pet market is an inevitable trend, and the resulting demand for pet food does not need to be said. However, what is the market prospect of pet food processing?

According to statistics, the annual sales of China's pet industry has exceeded 180 billion yuan. According to this trend, the annual sales this year can reach more than 200 billion yuan, becoming one of the important pillar industries of national economic development. It can be said that the overall development of China's pet industry is on the rise. At this time, borrowing for pet food processing will be promising.

Two processing technologies of dog food: 1. During the production and processing of dry expansion, water needs to be added to the raw materials. The raw materials do not undergo pre conditioning treatment before entering the expansion bin. All the heat generated in the expansion process is generated by the raw materials through the screw, shear plate and expansion chamber under the action of mechanical extrusion. It is generally applicable to medium and small pet food processing manufacturers.

湿法膨化法与干法膨化的区别则是在进入膨化之前预行原料的调制,通过蒸汽或者水份以提高温度,预先熟化。所谓的调质就是指通过蒸汽对宠物食品原料进行热湿作用,使原料中的淀粉预先糊化、蛋白质变性提高狗粮的膨化制粒效果和提高膨化质量。 多数应用于中、大型宠物食品加工厂家。

宠物食品与传统饲喂方法有着大的差别,本设备以玉米、大豆(豆饼),混合料等为原料,直接加入机械内即可膨化生产不同颗粒形状新颖、口感特、营养丰富、组织细腻,适合于狗、猫、鸟、兔、貂、等不同宠物口味的饲料。适用于养殖户、中小型饲料厂和研究机构。营养成份齐全,杀菌减少鱼病玉米膨化机

The difference between wet expansion and dry expansion is that the raw materials are prepared before expansion, and the temperature is increased by steam or water. The so-called conditioning refers to the heat and moisture effect of steam on pet food raw materials, so that the starch in the raw materials is pre gelatinized and the protein is denatured, so as to improve the expansion granulation effect and expansion quality of dog food. Most of them are used in medium and large pet food processing manufacturers.

There is a great difference between pet food and traditional feeding methods. This equipment takes corn, soybean (bean cake), mixture, etc. as raw materials and can be directly added into the machine to produce different pellets with novel shape, special taste, rich nutrition and delicate tissue. It is suitable for dogs, cats, birds, rabbits, minks and other pet tastes. It is suitable for farmers, small and medium-sized feed factories and research institutions. Complete nutrients, sterilization, reduce fish disease, corn puffer

售后服务

1.承接同类设备零部件的设计加工。

2.为您设计合理的包装运输方案、申请运输,派技术人员上门安装调试、培训人员。

3.协助您进行设备选型、工艺流程设计、厂房优化布局,如有需要,可上门服务。

4.可根据您的需求进行设计制造及应用试验,并提供针对性的培训。

5.可针对您的产品,设计原料变化的补偿方案,并进行现场演示。提供基础配方。

6.设备保修壹年,供应零配件。

7.为您提供有关市场、设备、工艺、原辅料、包装等方面的咨询。

济南美腾机械有限公司是一家食品机械的研发、设计、制造、销售、工程、服务为一体的生产厂家。自成立以来,从事膨化机械的制造和食品机械的技术开发,一切以客户利益为宗旨造就了本公司在广大客户群体中的良好口碑。公司产品包括双螺杆、单螺杆膨化机、自动连续式油炸锅、夹心米果小食品生产线、宠物食品生产线、三角月牙小鱼沙拉生产线、营养米粉生产线、油炸面食生产线、螺旋贝壳生产线、狗咬胶生产线、早餐谷物玉米片生产线、组织蛋白生产线、再生大米生产设备、小型方便面生产线等。公司凭借行业内人才和技术精英的优势,并结合自身“务实、创新、进取、以诚为本”的经营理念,以“认真、主动、严格、”的做事风格,向用户提供高品质的产品。公司以雄厚的技术实力,高品质的产品,合理的价位,完善的服务,愿真诚与您合作,共创未来。生产线**:印度、泰国、印尼、东欧、南非、马来西亚、印度尼西亚、巴基斯坦、东南亚、中东等等众多国家和地区,深受客户的**。

欢迎来到济南美腾机械设备有限公司网站,我公司位于泉水众多,素有“四面荷花三面柳,一城山色半城湖”美誉的济南市。 具体地址是山东济南天桥区公司街道地址,负责人是王经理。

主要经营双螺杆膨化休闲食品生产线,宠物饲料加工设备,小型方便面机械,通心粉加工机器。

本公司供应食品机械 休闲食品机械 膨化机械 等产品,将以“优质,诚信”为宗旨,向您提供满意的产品,完善的服务。竭诚欢迎您的惠顾。

本页链接:http://www.cg160.cn/vgy-85880155.html

以上信息由企业自行发布,该企业负责信息内容的完整性、真实性、准确性和合法性。阿德采购网对此不承担任何责任。 马上查看收录情况: 百度 360搜索 搜狗

关于济南美腾机械设备有限公司

商铺首页 |

更多产品 |

联系方式

济南美腾机械有限公司是一家食品机械的研发、设计、制造、销售、工程、服务为一体的生产厂家。自成立以来,从事膨化机械的制造和食品机械的技术开发,一切以客户利益为宗旨造就了本公司在广大客户群体中的良好口碑。公司产品包括双螺杆、单螺杆膨化机、自动连续式油炸锅、夹心米果小食品生产线、宠物食品生产线、三角月牙..

- 我要给“狗粮 好用的宠物饲料机器厂商 猫粮生产线批发”留言

- 更多产品

相关分类