- 产品描述

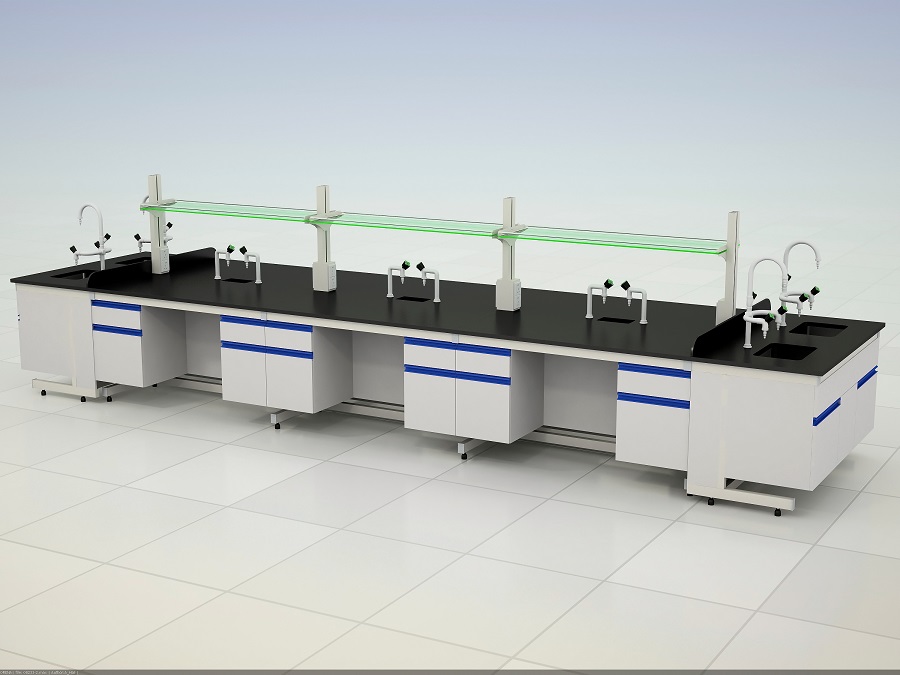

一、焊接头带式鱼型口罩机基本介绍Basic introduction 焊接头带式鱼型口罩机:秦泰盛公司依据客户需求,通过PLC编程控制,通过自动上料,内置鼻梁条、打印LOGO、超声波封边、一次裁边、超声波封边、二次裁边、头带1焊接、头带2焊接、成品下料等工艺一次成型,成功研发设计出全新的全自动鱼型口罩机,本机具有自动化程度高,操作简单,较人性化的特点。 Welding head belt type fish mask machine: Qin-tech company according to customer requirements, through the PLC programming control, through the automatic feeding, built-in bridge of the nose, LOGO printing, ultrasonic sealing side, a cutting edge, ultrasonic sealing side, the secondary cutting edge, head take 1 welding, the head to take 2 welding, finished product material under a molding technology, developed successfully designed a new type automatic fish face mask machine, this machine has high degree of automation, simple operation, more human characteristics. 二、焊接头带式鱼型口罩机设备技术参数 Technical Parameters ?型号:AMM-1-2F Model: AMM-1-2F ?材料:两层无纺布两层熔喷布(较多可以到6层) Material: 3-4 ply of non-woven fabric(Up to 6 floors) ?电压:AC 220V,50HZ Voltage: AC 220V, 50HZ ?功率:9KW Power:9KW ?重量:1500KG Weight: 1500KG ?外观尺寸: 长宽高:8500(L)*1500(W)*1950(H) Size: Length, width and height:8500(L)*1500(W)*1950(H) ?效率: 60±10 pcs/min Efficiency: 60±10 pcs/min ?产品规格:可依据客户要求进行定制 Product specifications: can be customized according to customer requirement. ?适用行业:一次性医疗防护用品 Applicable industries: disposable medical protective equipment 三、焊接头带式鱼型口罩机产品特性Product Features 整机由料架部分,内置鼻梁条、打印LOGO、超声波封边、一次裁边、超声波封边、二次裁边、耳带1焊接、耳带2焊接一次成型,成品下料,采用伺服电机,超声波焊接技术完成生产。 The whole machine is made up of material frame, built-in nose bridge, printed LOGO, ultrasonic edge sealing, primary cutting, ultrasonic edge sealing, secondary cutting, ear belt 1 welding, ear belt 2 welding one-time forming, finished material blanking, using servo motor, ultrasonic welding technology to complete the production. 1.料架部分:自动送料,刹车配合控制器,保证材料张力。 1.Material rack part: automatic feeding, brake cooperate with controller to ensure material tension. 2.鼻梁条部分:采用调速电机控制自动输送鼻梁条配合齿模超声波焊接 2. Nose bridge section: the cylinder is welded by ultrasonic wave, and the nose bridge is automatically conveyed 3.打印LOGO:可定制LOGO。 3.Print LOGO:Customizable LOGO. 4.外形熔接部分:定制齿模配合超声波,完成纹路焊接。 4.Shape welding part: the mold is matched with ultrasonic wave to complete the texture welding. 5.外形切刀部分:定制切刀,滚切成型 5.Shape cutter part: customized cutter, roll-cutting forming. 6.耳带焊接:采用全伺服控制效率高每分钟可高达60PCS(±10%)后期维护成本低,配合超声波完成耳带线焊接。 6. Adopt full servo control, high efficiency, up to 60PCS per minute (±10%), low maintenance cost in later stage, and complete the welding of ear strap line with ultrasonic. 7.成品输出:口罩成品输出,收集。 7. Output of finished products: output and collection of finished masks.

欢迎来到广东秦泰盛智能化科技有限公司网站,我公司位于素有“龙舟之乡、中国民间艺术之乡、举重之乡、粤剧之乡”之美誉,号为“世界工厂”的东莞市。 具体地址是广东东莞长安公司街道地址,联系人是。

主要经营广东秦泰盛智能化科技有限公司主要经营:气凝胶贴双面胶设备-喇叭贴背胶机-电池贴绝缘片设备-散热片贴背胶机-PCB贴辅料机-FPC贴背胶机 。

单位注册资金:人民币 10 万元以下。

“因为专注,所以专业”,我公司将一如既往的倾尽公司全体员工的心血为您生产优质的产品。欢迎新老客户来电垂询。

本页链接:http://www.cg160.cn/vgy-57500619.html

以上信息由企业自行发布,该企业负责信息内容的完整性、真实性、准确性和合法性。阿德采购网对此不承担任何责任。 马上查看收录情况: 百度 360搜索 搜狗

- 产品推荐

- 无锡缸套离心铸造工作原理 新劦诚供应 大林橡胶 玉树通风离合器厂家 鹿城区永磁同步电机批发 诚信经营 温州坤格自动化科技供应 福州气胎离合器厂 结构简单-拆装容易-检修方便 河南大林 盘锦通风离合器厂家 大连卷帘式伸缩防护罩电话 点击了解 上海蠕动式点胶机供应商推荐 江浙沪点胶 上海亚哲电子科技供应 PDER-50T轴承加热器/升级款外径500MM 长沙卷帘式伸缩防护罩规格 服务好 宁波卷帘式防护罩型号 便于安装 LJ-RF-6000W 忻州液压杆激光熔覆设备立匠激光 增材 龙港市液压伺服电机批发 欢迎来电 温州坤格自动化科技供应

- 相关文章

- 二氧化硅气凝胶贴辅料机 石墨烯气凝胶自动贴胶设备气凝胶隔热保温贴合设备 纳米气凝胶隔热贴辅料机纳米气凝胶贴双面胶机 隔热气凝胶自动贴胶设备 隔热材料贴合设备 纳米气凝胶隔热棉自动贴辅料设气凝胶贴合机 新能源气凝胶贴装机 气凝胶贴膜机**级隔热板贴合机新能源气凝胶隔热片贴背胶机高速每小时1000PCS 兼容450隔热板新能源气凝胶隔热板贴装机 气凝胶隔热片贴合机 气凝胶贴辅料机新能源**级隔热板贴合设备 隔气凝胶隔热棉贴背胶机热垫自动贴装**级隔热板贴合设备 气凝胶贴背胶机 新能源电池贴装设备全自动连线贴膜机 气凝胶贴辅料设备 新能源隔热板贴合设备**大尺寸FPc软板贴辅料设备 自动贴辅料机 FPC贴辅料设备fpc软板自动补强设备 全自动补强机 柔性线路板贴加强片设备

关于广东秦泰盛智能化科技有限公司

商铺首页 |

更多产品 |

联系方式

- 我要给“KF94口罩机 全自动一拖一鱼型口罩机 口罩生产设备 口罩机械厂”留言

- 更多产品

相关分类